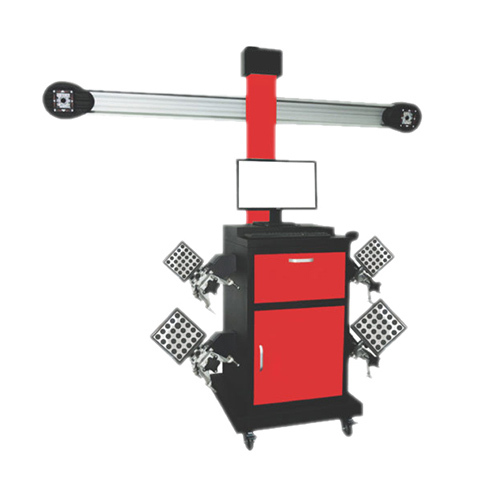

Truck Alignment Machine

Product Details:

Truck Alignment Machine Price And Quantity

- 1 Unit

- 1260000.0 INR/Unit

Product Description

A truck alignment machine, also known as a heavy-duty wheel aligner, is a specialized piece of equipment designed to measure and adjust the suspension and steering angles of large commercial vehicles like semi-trucks, buses, and heavy-duty trailers. This is a critical service for maintaining safety, extending tire life, and improving fuel efficiency, as the heavy loads and long distances these vehicles travel place significant stress on their alignment.

Key Alignment Angles

The machine's primary function is to measure and help a technician adjust three key angles:

-

Toe: This refers to the direction the wheels are pointing when viewed from above. "Toe-in" means the front edges of the wheels are closer together, while "toe-out" means they are farther apart. Incorrect toe causes tires to "scrub" against the road, leading to rapid and uneven tire wear.

-

Camber: This is the vertical tilt of the wheel when viewed from the front. "Positive camber" means the top of the wheel tilts outward, and "negative camber" means it tilts inward. Improper camber can lead to uneven tire wear on the inside or outside of the tread.

-

Caster: This angle refers to the forward or backward tilt of the steering axis when viewed from the side. Caster is crucial for steering stability and for ensuring the steering wheel returns to the center after a turn. An incorrect caster can cause the vehicle to wander or pull to one side.

-

Thrust Angle: For a multi-axle vehicle like a truck, this is a particularly important measurement. It determines if all the rear axles are aligned with the vehicle's centerline. A misaligned thrust angle can cause the truck to "dog-track" (drive sideways down the road), leading to severe tire wear and poor handling.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Alignment Machine' category

|

Dhavi Machine Private Limited

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send SMS

Send SMS